Technology

Nanojet Principles

Aerodynamic Focusing

The NanoJet Printhead uses aerodynamic focusing as a sheathed, aerosol-laden stream traveling through a cylindrical channel is passed through an orifice, undergoing one contraction upstream of the orifice and one subsequent and immediate expansion downstream of the orifice. A contraction of the aerosol stream is produced as the flow approaches and passes through the orifice. The gas then undergoes an expansion as the flow propagates downstream into a wider cross-sectional area. Flow through the orifice forces particles towards the flow axis, so that the aerosol stream is narrowed and collimated.

Hydrodynamic Focusing

Hydrodynamic focusing using a sheath gas is generally accomplished by propagating an annular sheath/aerosol-laden inner flow through a continuously converging nozzle using differing sheath and aerosol gas flow rates. The degree of focusing is proportional to the ratio of the gas flow rates. As the sheath gas flow is increased, the volume available for the aerosol-laden inner flow is decreased so that the aerosol stream is stretched to a reduced diameter as the combined flow passes through the nozzle orifice.

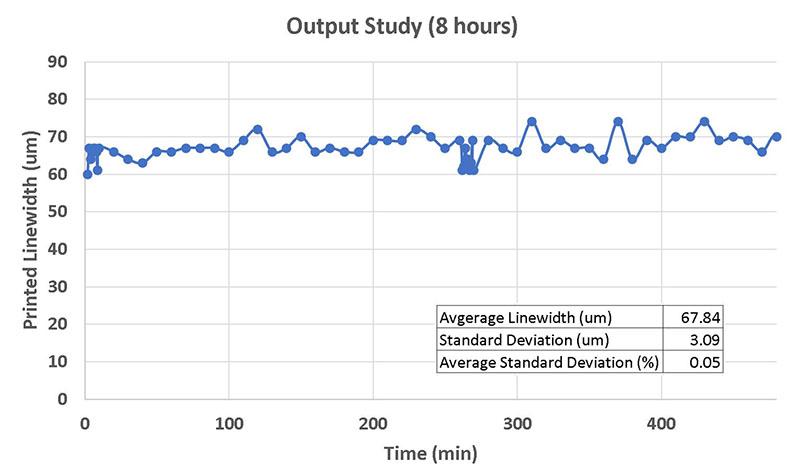

8-Hour Print Stability

The NanoJet process and apparatus are designed to provide multiple hours of stable, unassisted operation. NanoJet stability has been characterized in studies of line width as a function of time. In a typical stability study, printing is started and maintained for several hours, and linear traces of silver nanoparticle ink are deposited on a glass substrate at five or ten minute intervals.

Modular Design

The NanoJet Print Module uses a modular design with removable ink cartridges that can be quickly changed to print different inks.